Features

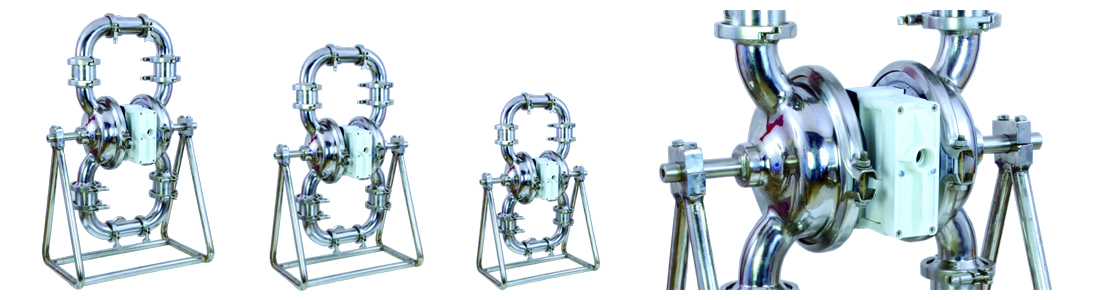

- Polished 316L SS construction (passivated stainless steel)

- Sizes available: 1”, 1 ½” e 2” (3” under development)

- Connection available: Tri-clamp®, DIN or SMS

- PTFE (FDA and USP class VI ) and Buna diaphragm options available

- Swivel stand available

- Easy cleaning valve system

- Suitable for sanitary & hygienic applications

- Advanced and efficient air valve

- Handles a wide variety of fluids including viscous and with solid parts

- Delicate handling of sensitive products

- Self priming and dry run ability without damage

- Suitable for CIP (clean in place ) & SIP (steam / sterilize in place)

- Engineered to meet the highest standards and requirements in the industry

- Multiple certificate levels available under request

- Main applications: food, beverage, dairy, personal care and pharmaceutical

Technical Data

| Max Capacity: | 480 l/min |

| Max Head: | 7 bar |

| Max Suction Lift – Dry Condition: | 4,5 m (Rubber Diaphragm) |

| 3 m (PTFE Diaphragm) | |

| Max Suction Lift – Wet Condition: | 7,3 m (Rubber Diaphragm) |

| 5 m (PTFE Diaphragm) | |

| Max Viscosity: | 10.000 cps (mPas) |

| Temperature Limits: | -10 ÷ 100 °C |

| Contacts surfaces: | Ra 8.0 μm (Polished) |

| Max Particle Size: | 6,3 mm |

| Air Inlet Pressure: | 3 ÷ 7 bar |

| Size available: | 1” e 2” |

| (3” under development) | |

| Connections available: | Tri-clamp®, DIN or SMS |

Wetted Parts Material

Polished SS316L

| Model | Body | Diaphragm | Ball Valve | Valve Seat | O-Ring |

| STT | Polished SS316L | PTFE + Neoprene | PTFE | Polished SS316L | PTFE |

| SBT | Polished SS316L | Buna | PTFE | Polished SS316L | PTFE |

Notes:

- The above data refer to a positive suction head operating with water at room temperature.

- All the information indicated may vary without notice.